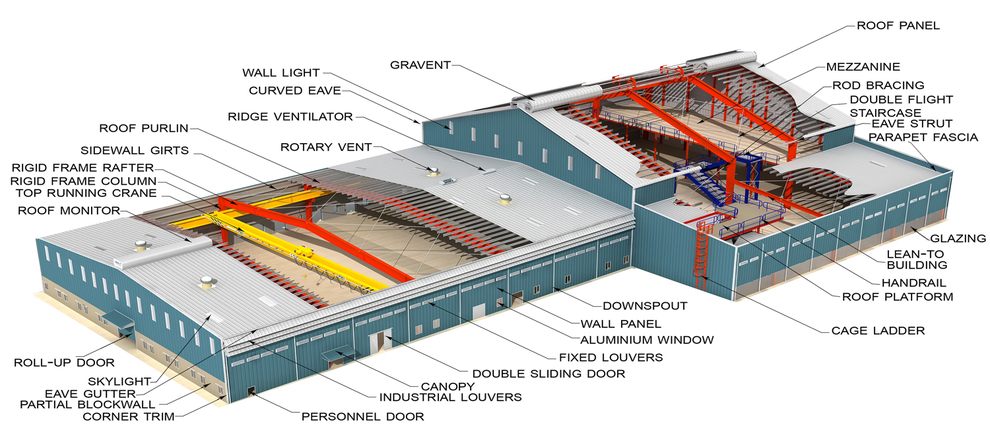

Pre-engineered buildings are the factory-built buildings of steel that are shipped to site and bolted together. PEB (Pre-engineered Building) revolution the construction market using built up sections in place of conventional hot rolled sections. Pre-engineered buildings are suitable for both, industrial and commercial operations.Reliable Solutions Pre-Engineered Buildings offer modern solutions to all building constructions along with the benefits of superior quality, efficiency, and durability.

Advantages Pre-Engineered buildings offer:

Pre-Engineered buildings are tailor-made solutions as per customer’s needs and are custom designed to meet exact requirements:

- Easy integration of all traditional construction materials such as brickwork, glazing, timber, etc.

- Optimization in accordance with customer’s requirements.

- Addition of canopies as a direct continuation of the roofline or at a lower level with positive or negative roof slopes.

- Addition of parapets, partially or completely around the building.

- Weather-tight roof and wall coverings with accessories for maintenance-free exteriors

Design & Build:

PEB concept involves the steel building systems which are pre designed and prefabricated. As the name itself indicates, there is involvement of pre engineering of structural elements. The basis of PEB is to provide the section at the specified location only according to the need at that spot. The sections may differ along the length according to the bending moment. This system consists of factory-fabricated and factory-painted steel column and beam segments that are simply bolted together at site. The columns and beams are custom-fabricated I-section members that have an end plate with holes for bolting at both ends. Each piece of the system is very much alike I section with end plates for bolting. The painted steel sections are lifted into place by crane, and then bolted together by construction workers.

We do the Turnkey execution:

- All primary and secondary framing

- All connections

- Choice of two roof systems

- Choice of three wall systems

- All fixings

- All sealants for weather proofing

- Thermal or acoustic insulation

- Liner panels

- Flashings

- Integrated accessories

- Crane beams and rails

- Mezzanine floors